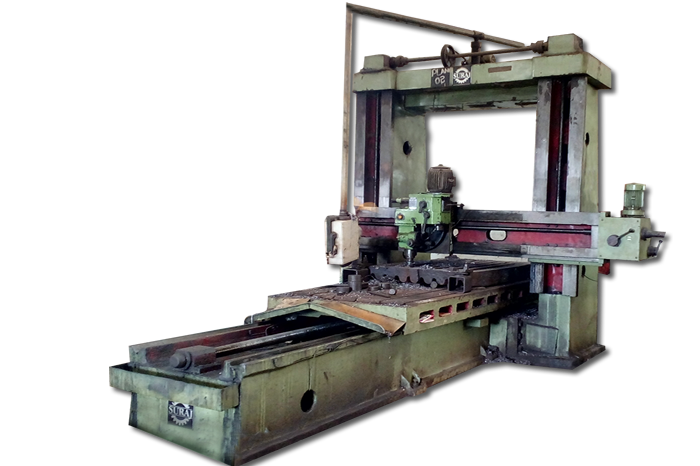

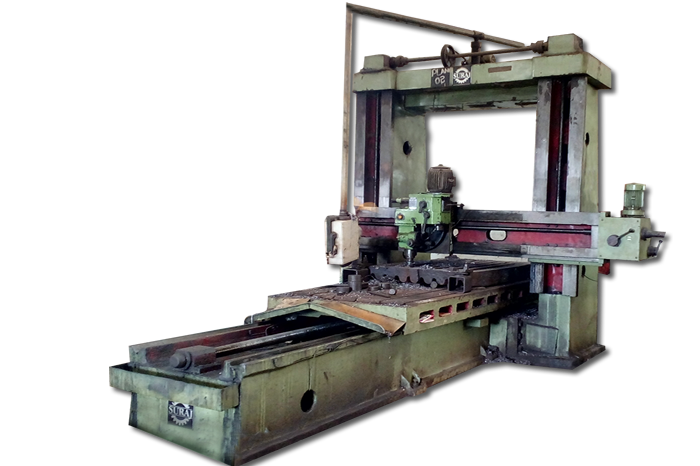

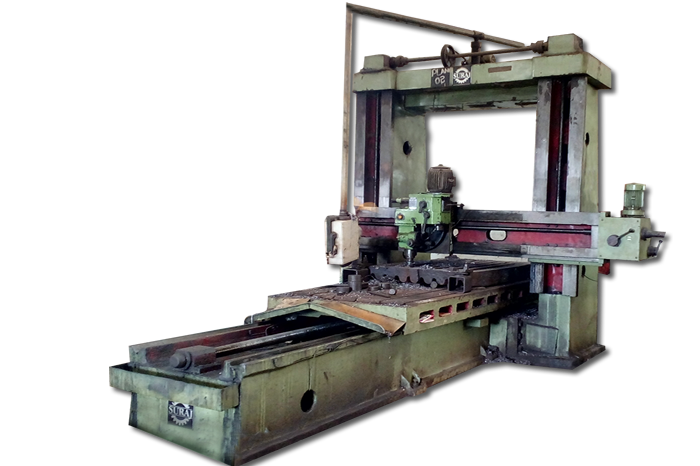

QUALITY CONTROL & TESTING - (FETTLING)

The removal of feeders and excess material from a casting is taken as the first stage of finishing a casting.

The metal removal is often achieved using manual cutting or grinding. However, more emphasis is being placed on automatic fettling, whereby the casting is placed in a machine programmed to remove materials from specific areas. The method of fettling must be taken into account at the initial casting design stage, so that the process is fast and efficient..

We are having the full-fledged fettling shop to meet out customer specifications with many automated facilities.

The facilities include the following,

(a) Straight Grinder - 7 Nos.

(b) Chippers - 12 Nos.

(c) Die Grinder - 2 Nos.

(d) Ag7 Grinder - 7 Nos.

(e) Swing Frame Grinder - 6 No.s, Size 400x53x152.4 mm

(f) Double Ended Post Grinder - 5 Nos.

(g) Flexible Shaft Grinder - 1 No, 9” Dia.

(h) Rectifier - 1200A 1No. & 600A 2Nos.

(i) Welding machines - 4Nos(400A 2Nos & 200A 2Nos).